Mechanical Turnkey Solutions (MTS) has been a leader in the feeding industry with over 25 years in the field. We design and build for multiple industries including but not limited to: Automotive, Aerospace, Glass, Lawn Equipment, and Food Packaging.

MTS specializes in feeding and placing parts. In addition to bowl building we have a full mechanical and electrical engineering department along with 3 manufacturing and assembly facilities to enable us engineer and build complete feed systems or full cells that can be integrated with presses, welders and robots.

Our feeding capabilities are the following but not limited to:

Our types of Placement Units & Presentations consist of the following but are not limited to:

Single or dual out nut feeder that escapes and blows a weld nut to our weld nut placement unit. This system is typically used to feed and place weld nuts onto sheet metal stampings. The placement unit is mounted on a pedestal welder where a robot will bring the stamping to several locations for the weld nuts to be applied. The axial placement unit can be set up at different angles depending on the nut and the stamping. It also comes in different lengths depending on the application.

Single or dual out stud feeder that escapes and blows a weld stud to our weld stud placement unit. This system is typically used to feed and place weld studs into sheet metal stampings. The placement unit is mounted on a pedestal welder where a robot will bring the stamping to several locations for the weld studs to be applied. The placement unit is set up at 3 different angles depending on the stamping and the weld process. It also comes in different lengths depending on the application.

This system feeds and blows a bolt to our presentation stand. The bolt is presented head up for robotic pickoff inside a robot cell by a rundown socket. This system is typically used to attach body panels like a door, hood, lift gate or fender. We have presented up to 8 bolts at once.

This system feeds and blows a nut to our presentation stand. The nut is presented for robotic pickoff inside a robot cell by a rundown socket. This system is typically used to attach body panels like a hood or fender. We have presented up to 6 nuts at once.

Feed and blow bolts to our design and build bolt rundown unit. Bolts are escaped and blown to our “Y” receiver on slides with the customer chosen bolt rundown motors. System can be used in a variety of applications including body attach, engine assembly, transmission assembly etc.

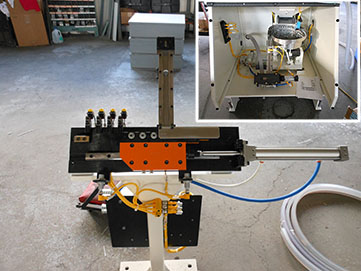

REO and MTS have combined our 30 years of fastner experiance to design special or standard feed and press systems. Most fastner companies offer installtion tooling for Heavy press. REO/MTS will intergate fastner tooling from any of these companies to provide a tunkey system. Additonally our complnies can provide custom solutions for any fastner using REO Group fastner tooling where heavy press tooling cannot be designed in.